Lock plug-custom made MIM parts can be used in door lock, padlock, coded lock etc. China Metal Injection Molding Parts Custom Lock Metal part for Lock knob-precision mim parts

Powder metallurgy Car intake system gear MIM parts Material: Iron-base alloy; China custom Powder metallurgy Parts

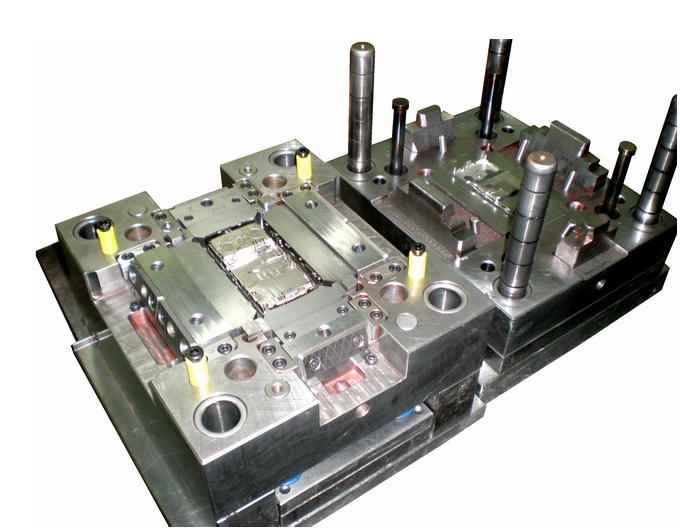

Description: during injection molding, the change of weight and size exceed the composite production capacity of the

mold, injection machine and plastic .

The possible causes and recommend remedy:

1. Injection machine

A. Material is uneven in the shot feeding cylinder.

Check whether there is sufficient cooling water flowing through the hopper throat to maintain the correct temperature.

B.Temperature or fluctuations range is too big for shot feeding cylinder

Check whether thermal electric coupling that used with temperature controller is the correct type.

C.Injection molding machine capacity is too small.

Check the injection volume of injection molding machine and plasticizing capacity, and then compare with the actual

injection quantity and plastic consumption per hour.

D.Unstable injection pressure.

Check whether each operation has a stable melting padding.

Check whether backflow prevent valve has leakage, if yes replace it.

Check if the wrong set of incoming materi

E.Screw reset is not stable.

Ensure that the screw in each operation reset position is stable, is not more than 0.4 mm (0.16 inch)

F.The change of the operation time, the melted fluid viscosity is inconsistent.

Check the operation time inconsistency.

Use the back pressure.

2.Molds

A. Gate partially blocked.

Check if any signs of gate residue in sprue hole, especially submersible gate.

B. Inconsistent mold temperature control.

Check whether the cooling medium has temperature changes.

3. Materials

Check the size change of the feedstock. Ensure that the smalls are picked out from the recycled material.

Check whether two batches of plastic mixed together.

It is common that dimensional deviation exists in the process of injection molding, by optimizing the die structure and

forming process parameters, choose the appropriate raw materials, can reduce or even avoid the size deviation, or

reduced size deviation, improves the performance of the plastic product, so that the products size and performance can

meet the design requirements.

Talk to Us

Our engineers are on hand to discuss your metal injection molding component requirements and advise on design parameters. Excellent service with Favorable Wholesale Pricing!

FAQ About us Products Equipments News Contact us

MIM manufacturer MDM Metal has been focusing on the manufacturing of MIM parts, MIM Components sintering parts and custom metal parts for years.Your satisfactory is our biggest honor.