Lock plug-custom made MIM parts can be used in door lock, padlock, coded lock etc. China Metal Injection Molding Parts Custom Lock Metal part for Lock knob-precision mim parts

Powder metallurgy Car intake system gear MIM parts Material: Iron-base alloy; China custom Powder metallurgy Parts

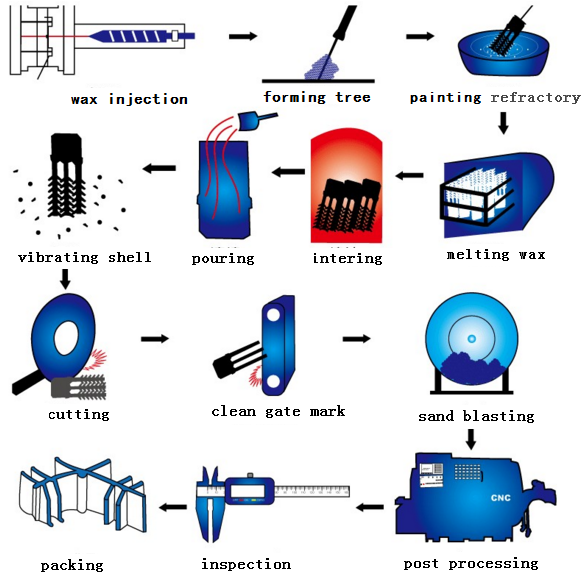

Investment casting also called lost_wax casting. This kind of casting process can produce sophisticated parts that close to the

final product shape,metal parts or fine arts and crafts while don't need or rarely need machining.It is a kind of near net shape

Metal liquid forming technology, and is widely applied.

Investment casting is batch replication technology uses the final product as transcription.

Talk to Us

Our engineers are on hand to discuss your metal injection molding component requirements and advise on design parameters. Excellent service with Favorable Wholesale Pricing!

FAQ About us Products Equipments News Contact us

MIM manufacturer MDM Metal has been focusing on the manufacturing of MIM parts, MIM Components sintering parts and custom metal parts for years.Your satisfactory is our biggest honor.